Troubleshooting Hardware Failures in a Datacenter: A Step-by-Step Guide from Real-World Experience

In my years managing enterprise datacenters, hardware failures have always been inevitable — but the speed and precision with which you respond determines whether downtime is measured in minutes or hours. This guide is based on real-world incidents I’ve handled, from failing storage controllers to overheated blade servers, and is designed to help you troubleshoot hardware failures systematically while avoiding common pitfalls.

1. Establish a Clear Incident Workflow

In a mission-critical datacenter environment, you cannot afford ad-hoc troubleshooting. You need a repeatable incident response framework.

Pro-Tip: Always maintain an up-to-date Hardware Asset Inventory that includes serial numbers, firmware versions, and warranty status. This reduces diagnosis time by up to 50%.

Recommended Workflow:

1. Detect: Automated monitoring (DCIM, SNMP, IPMI alerts) detects anomalies.

2. Validate: Confirm the alert is genuine (avoid false positives).

3. Isolate: Narrow down to the specific hardware component.

4. Escalate: Contact vendor support if under warranty.

5. Document: Record the failure, root cause, and resolution.

2. Rapid Identification Using Monitoring Tools

Most hardware failures show early warning signs before complete breakdown.

Tools I rely on:

– DCIM (Data Center Infrastructure Management) platforms such as Schneider EcoStruxure or Vertiv Trellis.

– IPMI/Redfish for out-of-band server health checks.

– Storage Array Management tools like NetApp OnCommand or Dell EMC Unisphere.

– Syslog/SNMP traps for proactive alerting.

Example: IPMI Health Check Command

bash

ipmitool sensor list

This command quickly surfaces temperature spikes, voltage drops, or fan failures without requiring OS access.

3. Isolate the Faulty Component

Common Pitfall I’ve Seen: Engineers often replace multiple parts at once, which wastes budget and complicates post-mortem analysis.

Best Practice: Use a controlled isolation method:

– Servers: Swap DIMMs or CPUs between slots to confirm fault location.

– Storage: Force failover to secondary controllers to check if the error follows the controller.

– Networking: Move links to another port or switch to rule out transceiver failure.

4. Perform Physical Inspection

Never underestimate the value of a visual inspection — I’ve caught burnt capacitors and swollen batteries long before automated tools flagged them.

Checklist for Physical Inspection:

– Look for burnt smell or discoloration on PCB.

– Check for unusual fan noise or vibration.

– Inspect cabling for looseness or wear.

– Ensure airflow paths are clear (blocked vents cause overheating).

5. Analyze Logs and Error Codes

Every enterprise-grade hardware device has diagnostic logs. The challenge is interpreting them correctly.

Real Example:

A Dell PowerEdge R740 reported “ECC error on DIMM B2”. Vendor documentation pointed to faulty RAM, but in my experience, consistent ECC errors on multiple DIMMs often indicate a failing memory controller rather than the DIMMs themselves.

Sample Log Extraction (Linux)

bash

dmesg | grep -i error

journalctl -xe | grep -i hardware

6. Engage Vendor Support with Precision

When escalation is necessary, providing complete diagnostic data speeds up RMA processing.

Data to Include:

– Serial number and service tag.

– Firmware/BIOS version.

– Full error log export.

– Steps already taken to isolate the issue.

7. Implement Preventive Measures

After resolving a hardware failure, strengthen your infrastructure to avoid recurrence.

Preventive Actions:

– Schedule quarterly firmware updates.

– Rotate and test spare parts inventory.

– Implement environmental monitoring for temperature, humidity, and dust.

– Automate daily health reporting scripts.

Example: Automated Health Report Script (Bash)

“`bash

!/bin/bash

HOSTS=(“server1” “server2” “server3”)

for HOST in “${HOSTS[@]}”; do

echo “===== $HOST =====”

ssh $HOST “ipmitool sensor list | grep -E ‘Temp|Voltage|Fan'”

done

“`

8. Real-World Recovery Timeline

Here’s a proven timeline I follow for critical hardware failures:

1. 0–15 minutes: Confirm alert and isolate affected system.

2. 15–30 minutes: Gather logs, run diagnostics, perform visual inspection.

3. 30–60 minutes: Escalate to vendor with complete data.

4. 1–4 hours: Implement temporary failover or redundancy measures.

5. 4–24 hours: Replace defective hardware and restore full service.

Conclusion

Troubleshooting hardware failures in a datacenter is about speed, accuracy, and documentation. By combining automated detection, structured isolation, and vendor collaboration — and learning from past incidents — you can significantly reduce downtime and protect SLA commitments. In my experience, the most valuable skill is knowing exactly where to look first, and having the discipline to follow a proven process every single time.

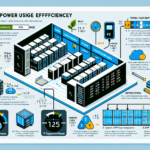

[Diagram Placeholder: Datacenter Hardware Failure Troubleshooting Workflow]